While you have numerous choices in the construction of your new office, there are few companies that offer the combination of architectural office design coupled with computer aided manufacturing right here in the USA. At Ennco, we take great pride in the accomplishments of our team of dedicated and highly trained individuals committed to competing in a global market place.

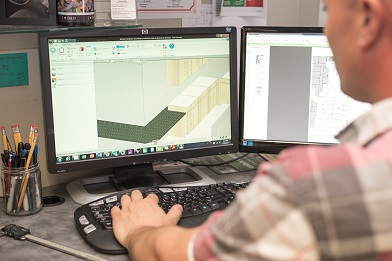

The journey of every project we tackle starts in our design office. While some interior projects require only bidding or color and finish assistance, the complexities of ADA requirements and general construction issues fall to our architect. The final details of casework, store fixtures and color and finish are critical parts of the process we go through for our tenant improvement projects but not what we focus the most energy on. Many of our clients need to remodel and stay open during that process. To assist in that regard, our tight integration with our own manufacturing and experience working with general contractors across the country makes that process smooth. Architects and contractors work in flat 2D plan sets, but they are hard to read for the average client. Our business model of combining architectural services with manufacturing helps our retail clients and our contractor’s clients see their future (or existing) space in a visual format they can understand. We produce tenant plans in both 2D and 3D to ensure that attention is paid to every detail of space planning.

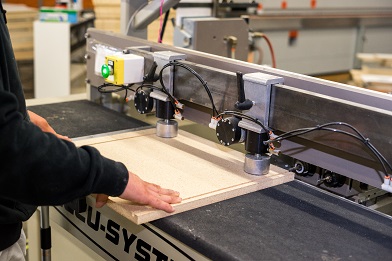

Once every detail of flow, room size and function have been finalized, the process of converting all those plans to action starts in our production department. Every finish, size, part and piece are specified to be ordered or produced. We utilize state of the art software that we have coded in-house along with industry software to allow us to use “nested base” machining of many parts. Our machining process “nests” parts side by side onto large sheets and allows for all the drilling and cutting to be done in one continuous process. The accuracy of this type of machining is most typically found in the metal working industry, but we use it in both our wood and plastic manufacturing to make each part identical.

We take extreme care on these parts and use computer controlled cutters adjustable to .1mm to get just the right edge finish on any required cut parts. To make our commercial casework virtually indestructible, we use a 5/8” solid back that joins the box with full dado and rabbet construction along with dowels and confirmat screws. While using dowels is an age-old joinery, it was boring to do by hand. We custom built a computer controlled machine to edge drill our panels and automatically insert the dowels and glue at a rate of one hole per second. The automation of this process was a big step forward for us on quick turnaround projects.

The production of store fixtures is similar but different from basic cabinetry construction. The addition of lights, extrusions, unique hardware or fixtures requires an attention to detail far beyond basic box construction. In many cases, it is required that parts and pieces be constructed of plastic materials. It seems only fitting that we started as a plastic company and when the need arises, we get to use one of our main strengths. From specialized gluing fixtures to custom bending equipment and laser cutting, we run the spectrum of plastic fabrication capabilities.

While we have specialized in retail optical space production for years, we have had the opportunity to assist in the design and production of numerous veterinary clinics, pet stores, dental offices, cosmetic surgery centers and general tenant improvement projects. If creating a special image is a concern for you, we have the tools to help you “show off your stuff”.

Our Equipment

400 Watt CO2 Laser

Lasers have made a major impact in guidance systems, surgery, manufacturing and countless other areas of technology in recent years. As a U.S. manufacturer, we are taking full advantage of our capabilities to bring high quality manufactured displays and other parts to the optical, beverage and airline industries.

When working with plastics, most lasers are designed to cut sheets sized to domestic standards (smaller range). However, to serve the global market, we reached out to a client and manufacturing partner back in 2013 to design and build a large format flying optics laser. We outfitted a 400 watt CO2 laser, and our cutting capabilities were extended to 80” wide by 120” long to accommodate the largest size imported sheet materials from Lucite®.

Larger sheet size is not the only advantage to our laser. The high wattage output allows us to run at much higher production speeds, creating smoother cuts and better polished edge finish on plastic parts. It also allows us to cut wood products with minimal burning.

All of this would not be possible if it were not for our advanced CAD capabilities. Ennco has been able to leverage these two technologies to bring customized products to our clients across multiple industries…some of which we would have never guessed.